FUNCTION AND ADVANTAGES

Dry air dryers are used for drying the moisture that has penetrated into hygroscopic polymers. It is also possible to heat the material before the process. In these devices, humid air is dried first by means of a sieve or roto dryer (dew point up to -50 ° C). Then the dried air is sent into the waiting polymer inside the boiler. It has a very good heat insulation and stainless steel boiler. The hot air is circulated in the polymer and the moisture is thrown into the atmosphere.

- All surfaces in contact with the polymer are stainless steel.

- Drying boilers were isolated with rock wool.

- The drying temperature is precisely controlled.

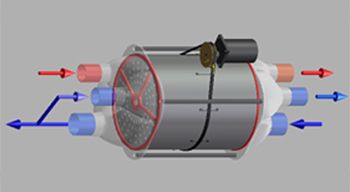

In the "HONEYCOMB" drying system, the DRYER ROTOR is available in a circular manner. The drying rotor rotates continuously around its axis and during this rotation, part of the rotor dries while the other part regenerates and dehumidifies it. Therefore, since the honeycomb rotor, which receives the moisture, discards any moisture from it without any waiting, there is no variation in the properties of the dry air produced

There are 80 and 600 m3 / hour NET dry air flow devices (excluding regeneration air). There are 2 separate blowers on it. One blower circulates the drying air, while the other blower circulates the regeneration air. Some companies recommend a single blower. In single blower systems, air flow rate is divided into two as drying and regeneration. In this case the capacity drops by about 30%

INVERTER TECHNOLOGY is available, so the dry air flow to the boiler is rated according to production capacity. The dry air flow rate is 50 kg / hour in a 400 liter boiler and the dry air flow rate is 100 kg / hour. Thus, as the energy is saved, the yellowing of the material does not occur due to over-drying.