Ningbo Yalishi Plastic Machinery Co., Ltd is specialized in manufacturing of highprecision plastic injection molding machine, providing qualified solutions for plastic products making.

The company has its own team of R&D, talented engineers and well experienced technicians, which some are Japanese engineers and some are well-trained in famous Japanese machinary companies. Take the advantage of advanced facilities and technology the company have developed standart, variable pump, servo energy saving and electrichydraulic models of machines.

We have set up more than 30 agents and technical support bases in main cities domestic China since 2005 and more than 10 overseas agents located in Africa, South America and Asia. All our products and service have been wining warm praise from our customers all over the world.

YALISHI owns a range of advanced processing equipments, so we can guarantee the good quality and prompt delivery for the workpieces manufactured by ourselves. We provide extended space for our customers in specification designs and it is easy for us to produce some special workpieces the customers request. Continuous R&D and introducing into new technology are our important aims in every stage.

High-capability servo motor dynamical control

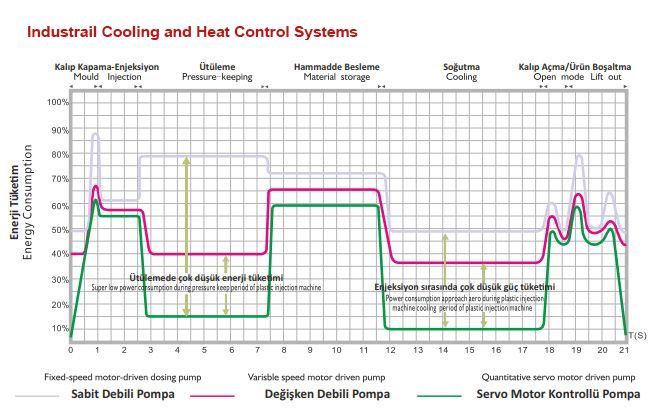

1.Super Energy Saving

Output power varies with the load, and no energy is wasted. In the holding pressure phase, the servo motor will reduce speed, with low energy consumption; during the cool-down period, the motor does not work, with zero power consumption. Compared with the ordinary injection molding machines, it can save 30% - 80% of the power.

2.High Precision and High Stability

Equipped with the precise pressure sensor, rotary encoder and pressure transducer, it can respectively monitör and feed back on flow and pressure. Based on the feedback, the high performance synchronous servo motor will adjust flow and pressure accordingly by changing the speed and torque. The closed-loop control can ensure the stability of product quality.

3.High Response and High Efficiency

The driving system responses with high sensitivity. It takes only 0.05 seconds to reach maximum value. The response speed is much faster than the ordinary injection molding machines. In that way, it significanly shortens the cycle time and increases the production efficiency.

Comparing with the hydraulic machine, AXS series can save more 50% of the power. Comparing with full electrical machine, energy saving is more obviously seen during pressure hold & cooling stage.

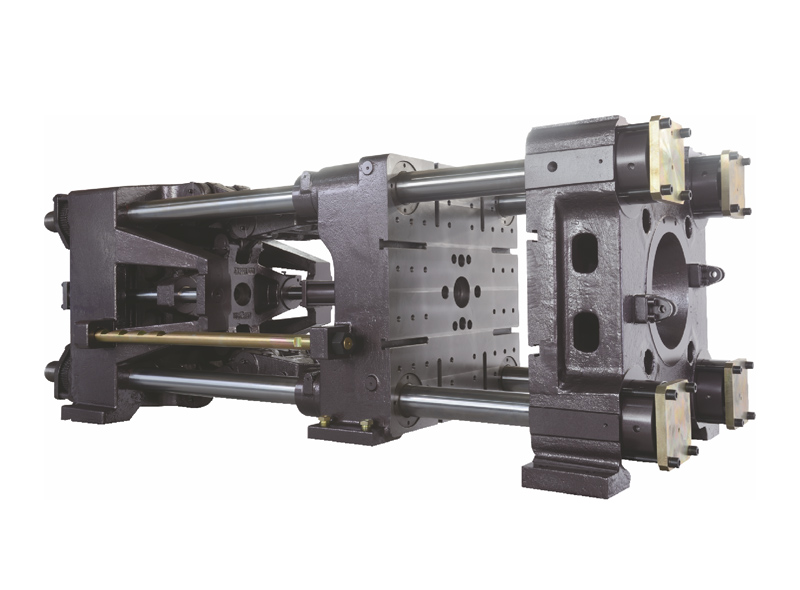

Clamping Systems

- Reinforce the clamping mechanism can meet the production demands of efficient and fast.

- The superior open model, run faster and more stable.

- Five-support crankshaft structure. The mold and the supports all use the portal structure, with good rigidity and high fitting precision.

- Professional optimization design template advanced finite element analysis software to optimize design, high rigidity, high strength, meet the demand of fast, impact conditions.

Injection Systems

- High strength mechanism structure design, assure long term precision.

- Double cylinder balancing injection mechanism makes the injection reliable and the pressure powerful.

- Precision electronic meter control on material injection, molten stroke.

- Professional plasticizing unit suitable for a variety of raw materials to produce Professional, dedicated heating power equipment, significantly improve plasticizing performance.

- Special designed screw for PET, PC, PMMA, UPVC, PMMA, PA, PC, CP, PPS, PET, etc.

- Powerful, humanized control system adopts special controller, a new man-machine interface easy operation, operation speed, good reliability and good extensibility.

- High-quality electrical components, enhanced hardware loop, stronger anti-interference ability, more reliable, more stable.

- High precision computer and high beauty combination, and economic efficiency overall speed to increase by more than 20% line machine is more efficient, make more cavity forming more stable.

- Hydraulic unit consist of world famous brands oil pump and control valves, more outstanding performance of pressure supporting. Ensure effectively the machine accuracy, reliability, stability and durability and low noise environmental features.

Servo-motor injection molding machine is energy-saving and loaded with high-performance servo motor power control system. Its power output can vary with load charge, which makes no excess energy loss; the servo motor automatically reduces revolving speed at the stage of pressure holding and without working at the stage of cooling, which will saves energy and water consumption, improve injection accuracy, and reduce noise.

Application Field

Injection molding machine can have a molding complex, the size is accurate or plastic with metal insert of the fine and close texture are widely used in national defense, electrical, automative, transportation, building materials, packaging, agriculture, education and health and peoples Daily life. Today with the rapid development of plastic industry, injection molding machine no matter in quantity or variety occupies an important position.